Designed custom test fixtures for autoinjector safety syringes at Instron, managing the full development cycle from initial concept through CNC production while navigating complex geometric constraints and tight machining tolerances.

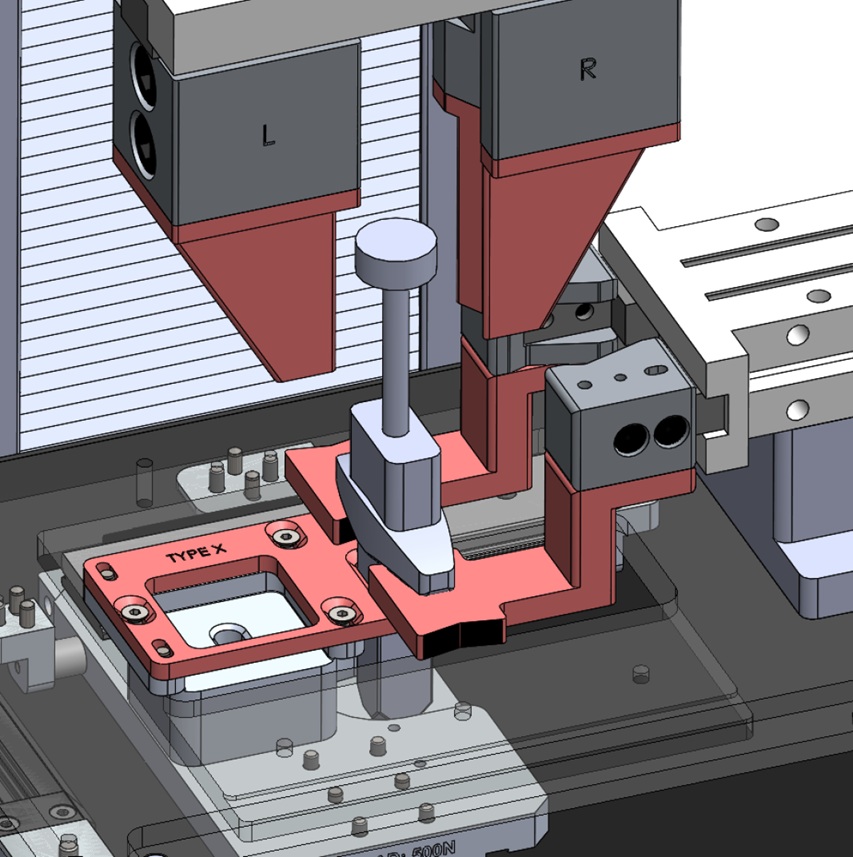

3D model of initial fixture design in SolidWorks

Design Challenges

The AutoInjector Test System needed fixtures to test safety syringe devices with complicated geometry. The challenge was designing fixturing that could accommodate both device sizes, securely grip only at rigid locations, remove caps without dropping them, and work with existing pneumatic grips—all while maintaining CNC-manufacturable tolerances.

Approach

I led the fixture development from concept to production, creating iterative CAD designs in SolidWorks and validating concepts through 3D-printed prototypes before committing to machined parts. The design required careful torque calculations to ensure grip usage stayed within safety factors and precise clearance management between moving components.

Key technical constraints included exact constraint theory application, GD&T specifications for manufacturing, and designing around existing mounting hardware while ensuring the fixtures could be produced efficiently on CNC equipment.

Results

Successfully developed and deployed fixtures that met all design constraints and passed validation testing. The system handled both device sizes reliably and integrated seamlessly with existing test equipment.

Skills Applied

CAD design, GD&T, exact constraint theory, design for manufacturing, verification & validation testing